Water Treatment For Closed Loop Systems

Heating and cooling system solutions.

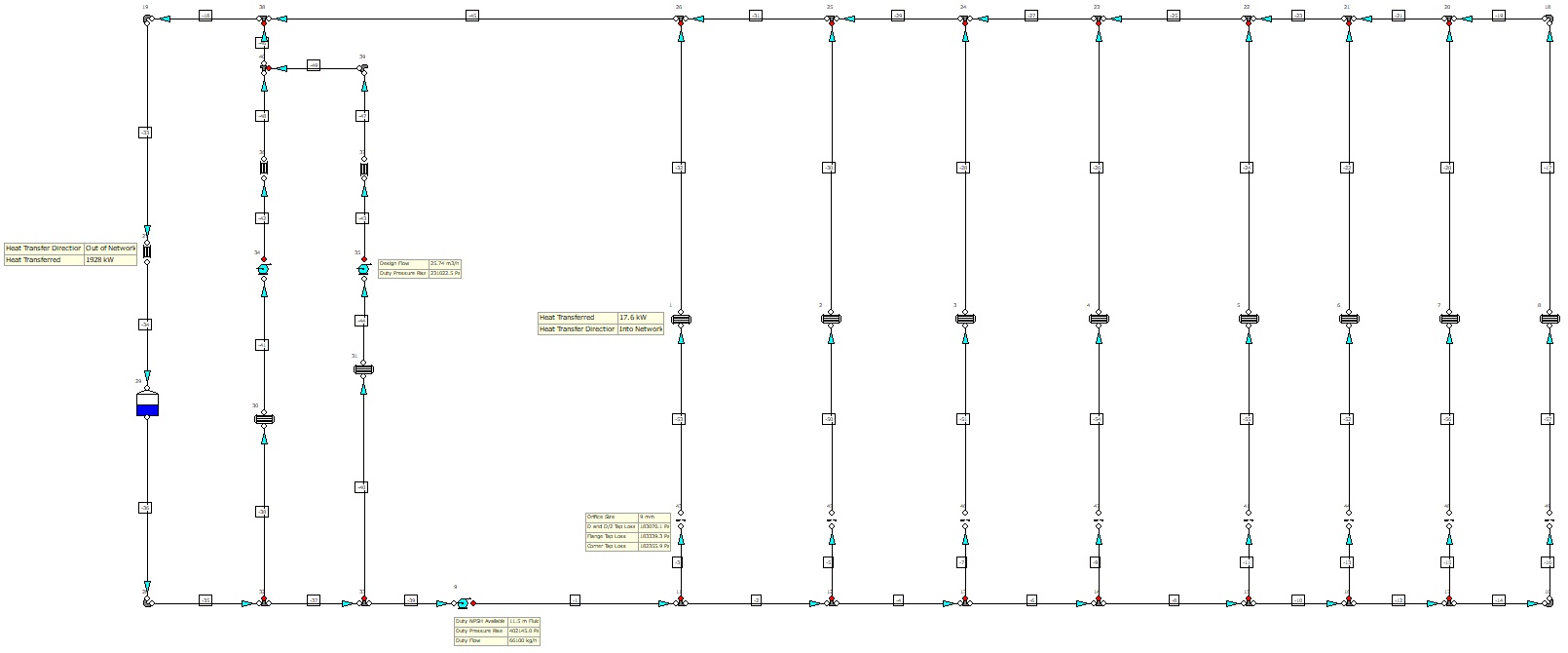

Water treatment for closed loop systems. This article looks at the points that need be considered when choosing a chemical dosing system for chiller water treatment and when one might be able to avoid them. For closed loop chilled water systems is treatment necessary. The importance of a closed loop water system for water treatment. Undiagnosed leaks permit air to enter the system allowing for corrosion and bacteria to begin contaminating the cooling water.

The water in your cooling or heating system dramatically affects performance. If you regularly monitor and treat the water in the cooling mechanism it will reduce problems from water deposits. When a closed loop cooling system is tight experiencing no water loss the chemical treatment that is applied can last for weeks or months before it needs to be refreshed. For more than 50 years chemicals such as nitrites have been used to control corrosion in closed loop chilled and hot water systems.

Whether you have a closed system that is a district network or a chiller heating network in a building this is often your most critical energy system. Hot water chilled water tempered water process water and glycol filled closed loops are often ignored when considering a water treatment program which can be a costly mistake. The chemicals attempt to coat all the metal surfaces to reduce corrosion but do not actually reduce the real problem dissolved oxygen. Chem aqua has the product line and technical expertise to recommend the appropriate treatment for the metallurgy in any closed loop system and monitor it after treatment is applied.

Your closed loop system is just as susceptible to malfunction as any open system. If so what is the procedure for implementing chiller water treatments.