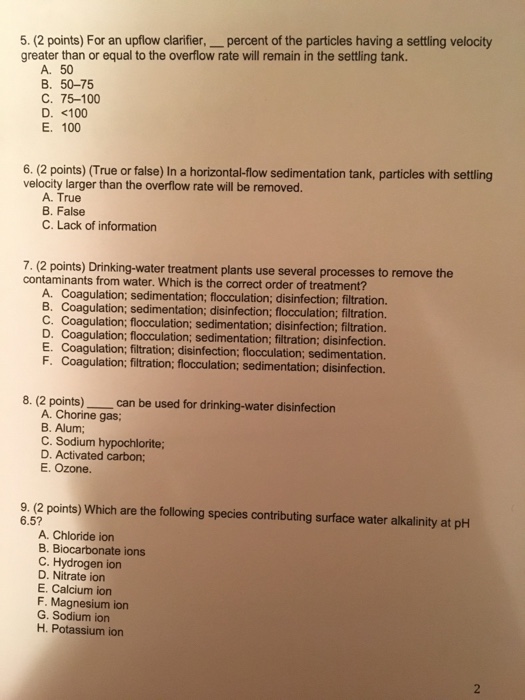

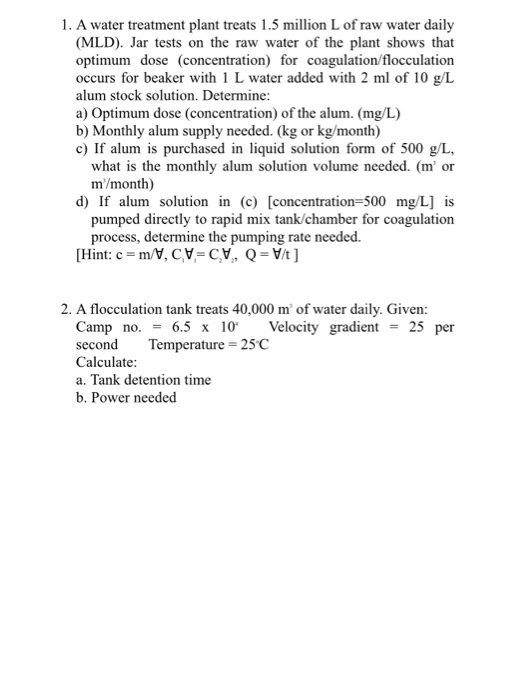

Water Treatment Coagulation And Flocculation Tank

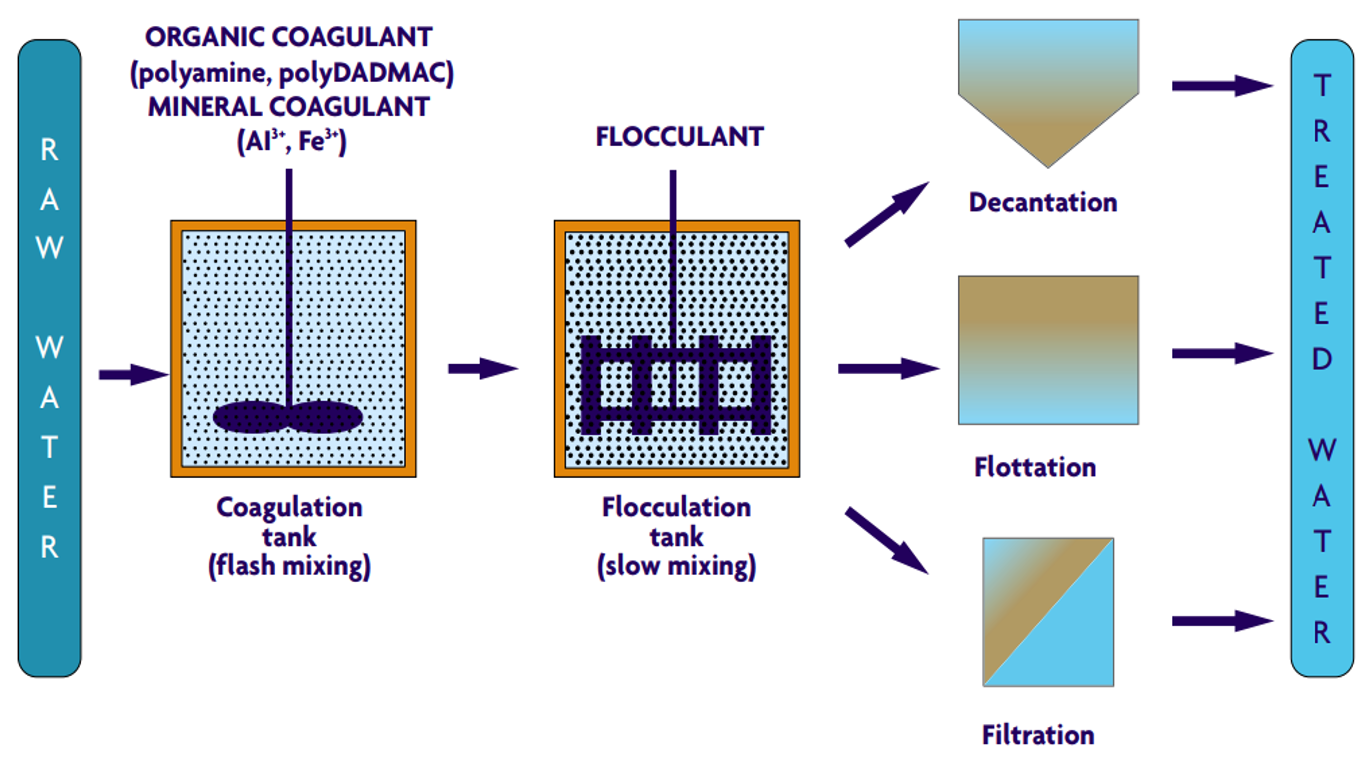

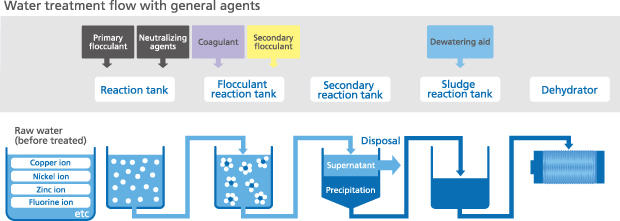

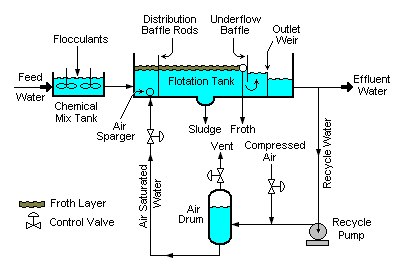

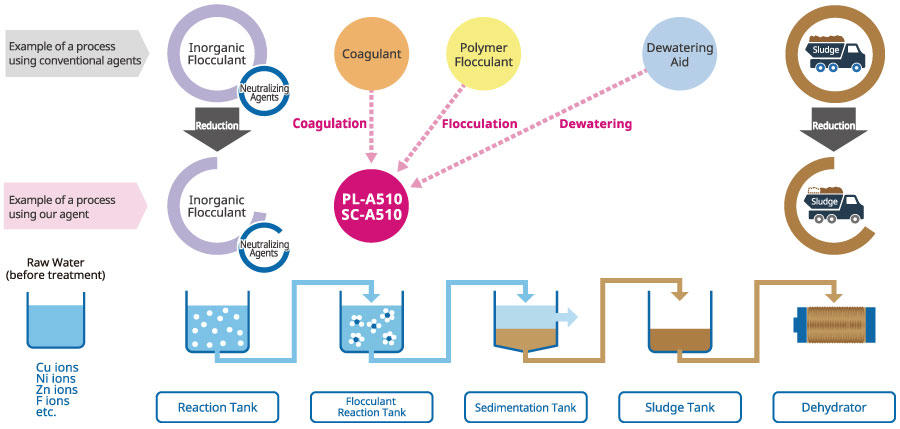

In water treatment coagulation flocculation involves the addition of compounds that promote the clumping of fines into larger floc so that they can be more easily separated from the water.

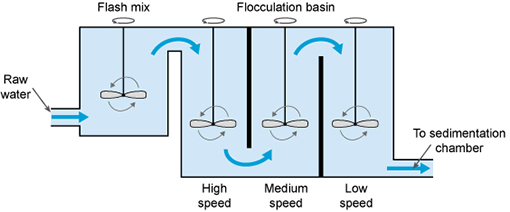

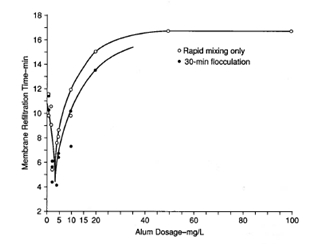

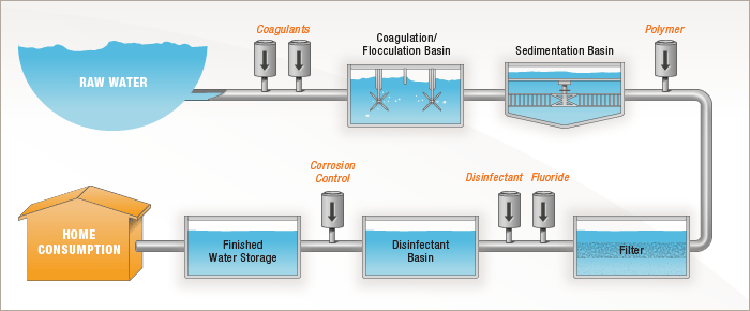

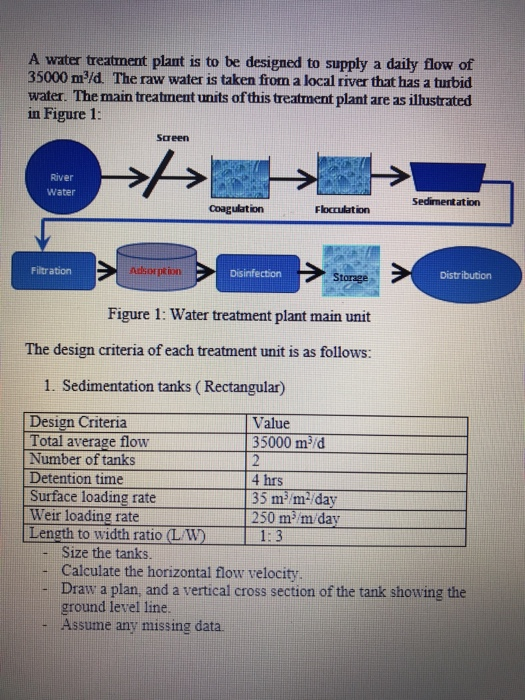

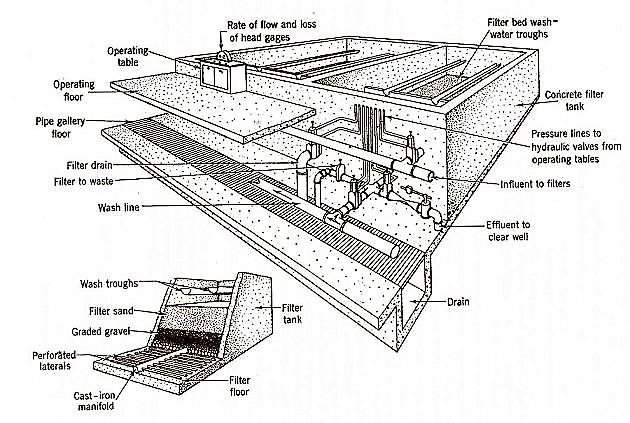

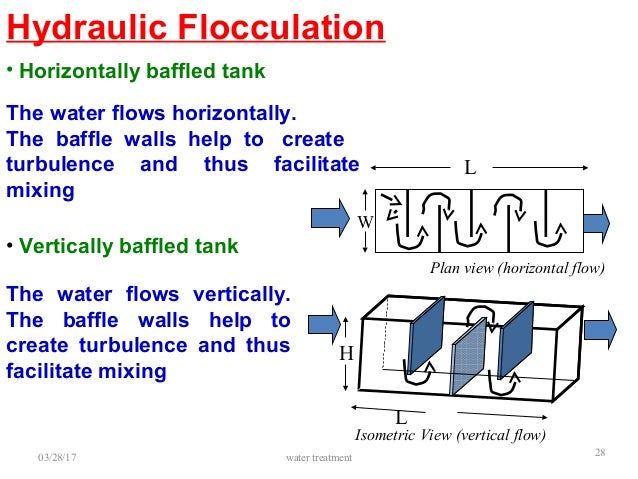

Water treatment coagulation and flocculation tank. Typical treatment processes consist of grates coagulation flocculation sedimentation granular filtration and disinfection. Coagulation is a chemical process that involves neutralization of charge whereas flocculation is a physical process and does not involve neutralization of charge. Some small water treatment plants combine coagulation and sedimentation in a single prefabricated steel unit called a solids contact tank. After flocculation the water flows into the sedimentation tanks.

Suspended solids mostly possess negative charge hence. Nevertheless coagulation flocculation is usually applied either as pre treatment or as post treatment step after sedimentation. In modern water treatment coagulation and flocculation are still essential components of the overall suite of treatment processes understandably because since 1989 the regulatory limit in the us for treated water turbidity has progressively reduced from 1 0 ntu in 1989 to 0 3 ntu today. Flocculation and sedimentation are widely employed in the purification of drinking water as well as in sewage treatment storm water treatment and treatment of industrial wastewater streams.