Cleaning Closed Loop Chilled Water System

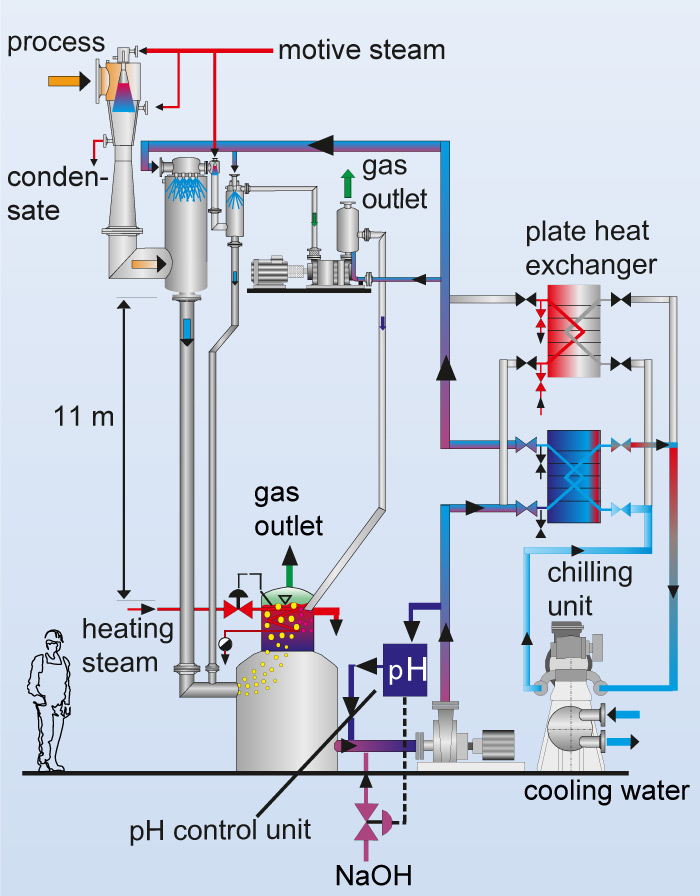

The most common chiller corrosion chemical is a closed loop nitrite borate silicate product.

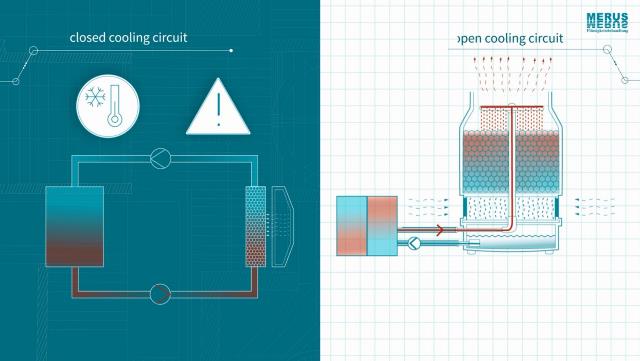

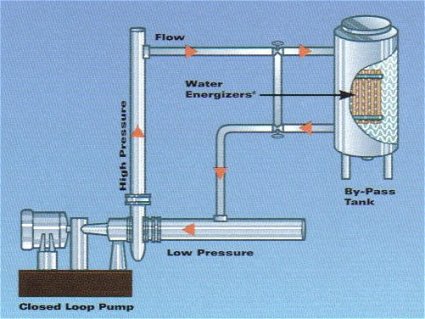

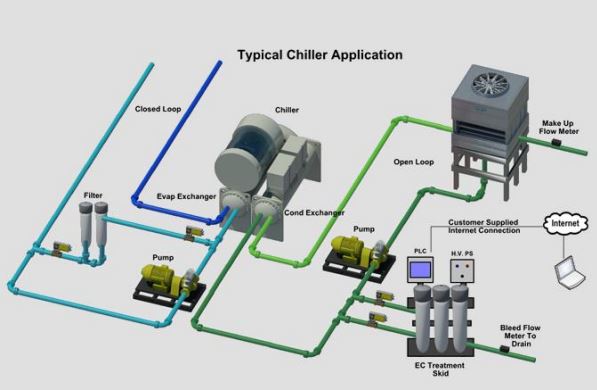

Cleaning closed loop chilled water system. Unfortunately most closed loop system designs do not account for this lost water by automatically adding closed loop treatment as make up water is added to the loop. Several chemical treatment methods have been developed for closed loop systems. Fill the system with clean water and drain the water after 30 minutes. Chiller chemicals why are chiller chemicals used.

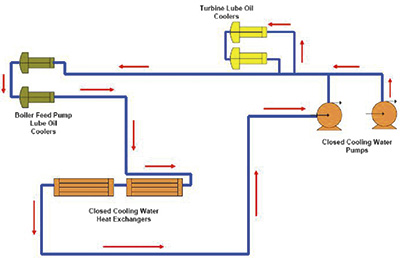

Refill the system with clean water and run the chilled water pump for 2 hours. The water in a closed cooling system is continuously recirculated. Industrial grade swab removes scale and corrosion by products from hot water re circulating boilers and chilled water systems. Regretfully sometimes this is not the case.

It tackles scale and its causes right at their source to eliminate problems before they happen. Have you thought about your closed chilled or hot water loop lately. Water lines piping valves tower fill cleans a closed loop system to keep it running right. The make up water not only dilutes the corrosion inhibitor and reduces its effectiveness but also adds oxygen which can promote corrosion on many surfaces.

Before doing the chemical treatment of any water piping system the flushing is must. This is characteristic of most chilled water systems and hot water heating loops. During the flushing process the drain valves shall be kept open while the pump is running until the. The second chemical is a cooling water biocide.

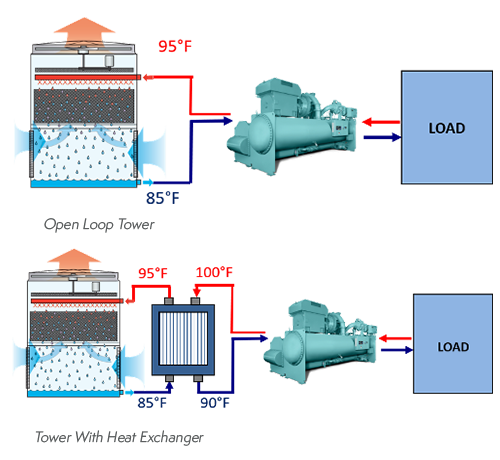

Other closed loop cooling systems can include chilled water systems for air chillers used at the air inlet to the gas turbines at a combined cycle power plant and the chemistry sample panel. Chilled water system is an ideal breeding ground of bacterial and other micro organism and it is necessary to control biological growth in the system supplier recommendation entail shock dossing of biocide chemical chem. If so what is the procedure for implementing chiller water treatments. 651 0 05 kgs per cu.

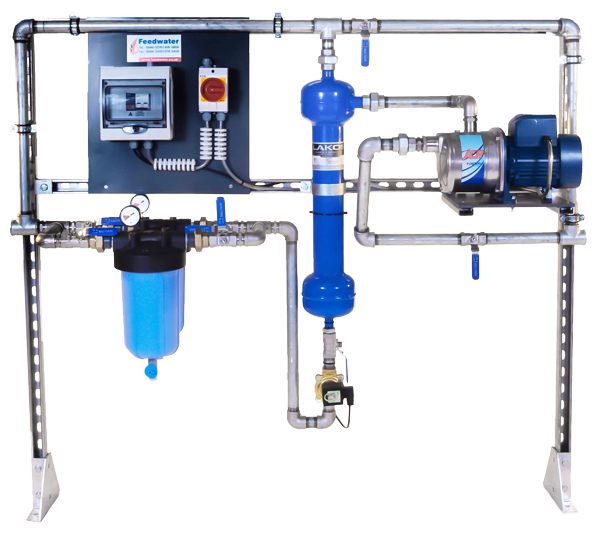

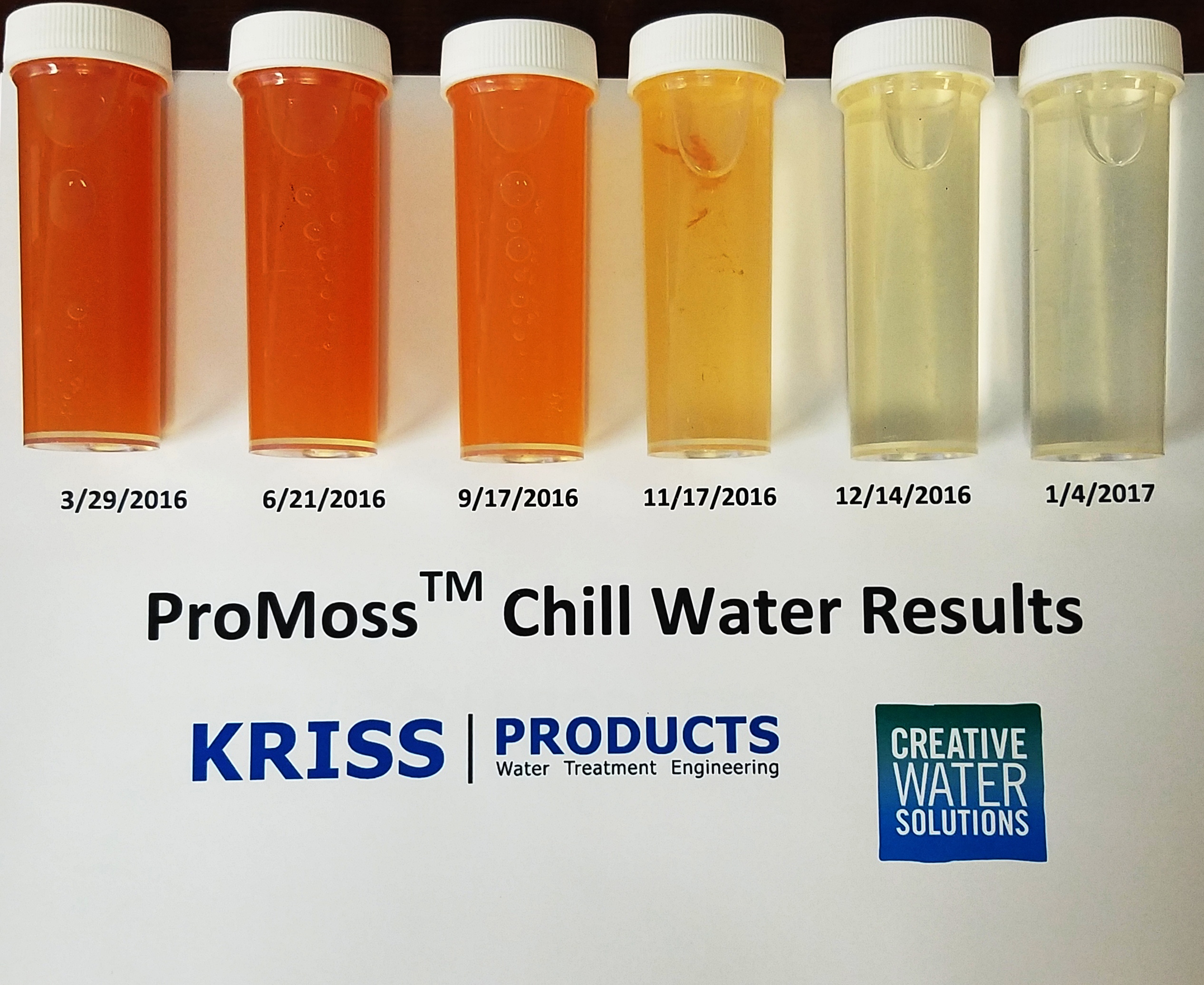

Open the drain valves in the main lines and drain the water completely. In a perfect world your systems would be chemically treated exhibit excellent corrosion rates and appear crystal clear. Below is a brief method statement for doing cleaning flushing and passivation of closed loop water cooling chilling system which is part of hvac system of a building. This article looks at the points that need be considered when choosing a chemical dosing system for chiller water treatment and when one might be able to avoid them.

Unless the system has a leak the makeup requirements are minimal. Mtr the product is closed into the system using the manual dosing pot and is closed once every three months in order to control the growth of micro. For closed loop chilled water systems is treatment necessary. Chiller chemicals are used to control corrosion and to prevent bacteria growth.

Flushing removes any solid particles or debris so that cooling water system remains clean.

.jpg)